Light burned magnesium ball Rotary kiln incinerator, also known as rotary kiln, is a slightly inclined steel hollow cylinder lined with firebricks. Most waste materials are heated by the gas generated in the combustion process and the heat transmitted by the kiln wall. Solid waste is sent into the kiln from the front end for incineration, and the purpose of mixing waste is achieved by rotating. When rotating, it is necessary to maintain a proper gradient to facilitate the sliding of solids. In addition, waste liquid and waste gas can be sent from the kiln head or the secondary combustion chamber, and even the whole barrel of waste can be sent to the rotary kiln incinerator for combustion.

Rotary kiln incineration technology is the most mainstream technology in hazardous waste incineration technology at present, which is the most widely used furnace type. It is a multi-purpose incinerator with strong adaptability and can incinerate a variety of solid, semi-solid, liquid and gas wastes. Combustible wastes of different types and shapes (particles, powders, blocks and drums) can be sent to the rotary kiln for incineration. When hazardous wastes are incinerated in a rotary kiln, they generally go through several stages, such as drying, pyrolysis, combustion and burnout. After these stages of light burned magnesium, the harmful components in the hazardous waste are fully decomposed and destroyed under the action of high temperature, forming high-temperature flue gas and slag. These high-temperature flue gas and slag will cause corrosive damage to the refractory laid in the rotary kiln.

(1) High temperature resistance. It can operate at high temperature above 800 ℃ for a long time.

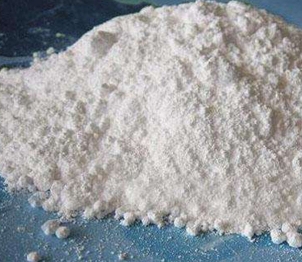

(2) High strength and excellent wear resistance. Light burned magnesium powder Refractories in the rotary kiln need to have certain mechanical strength to withstand the expansion stress at high temperature and the stress caused by the deformation of the rotary kiln shell. (3) Good chemical stability and thermal stability to resist the corrosion of chemical substances in flue gas and withstand the alternating thermal stress under incineration.

(4) Good thermal expansion stability. Although the thermal expansion coefficient of the rotary kiln shell is greater than the thermal expansion coefficient of the rotary kiln refractory, the shell temperature is generally about 150~300 ℃, and the temperature of the refractory is generally above 800 ℃, which may cause the refractory to be larger than the thermal expansion coefficient of the rotary kiln shell and easy to fall off. Due to the complex composition of the incinerated waste, it has a strong erosion effect on the refractories. After a period of operation, the refractories of the rotary kiln are easy to crack, loosen the brick joints, and produce asynchronous displacement and falling off between rings.