Light burned magnesium ball Furnace life is a comprehensive technical index for converter steelmaking. Increasing the furnace life can not only reduce the consumption of refractory materials, but also help to balance the organization of production and promote the virtuous cycle of production. Therefore, it is always the goal of iron and steel enterprises to greatly increase the converter life. The converter lining is usually eroded at the rate of 0.2-0.8 mm/furnace under the condition of high temperature and high oxidation. Slag splashing is a new technology developed in recent years to improve furnace life. The technology is to use the steel making end slag with MgO content saturated or supersaturated to cool and solidify on the lining surface through the splashing of high-pressure nitrogen, forming a layer of high melting point slag layer, which is well bonded with the lining. The slag splashing layer formed by slag splashing has good corrosion resistance, which can inhibit the oxidation and decarbonization of the furnace lining brick surface, and reduce the erosion and scouring of high-temperature slag on the furnace lining brick, thus protecting the furnace lining brick, reducing the loss rate of refractory materials, reducing the consumption of gunning materials, while improving the service life of the furnace lining, improving the converter operation rate, and reducing production costs.

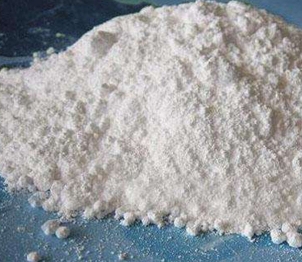

The light burned magnesium ball is made of highly active magnesium oxide as the main raw material, added with appropriate additives, and then mixed, pressed, or pelletized and dried.

Light burned magnesium balls are mainly used for converter steelmaking and slagging. The product is added into converter comprehensive slag and reacts quickly with the slag, which can effectively adjust the composition of comprehensive slag, make the main minerals in the slag phase change into MgO, C3S and C2S phases with high melting point, improve the viscosity and melting point of slag, thus significantly improving the effect of slag splashing for furnace protection. Therefore, light burned magnesium ball is a slag protection component modifier for converter slag splashing.

With the rapid development of metallurgical industry, open hearth steelmaking has been eliminated, and it is transitioning to large converter. The process of converter slag splashing is to use oxygen lance to blow nitrogen after the converter tapping to evenly splash the remaining slag containing a certain amount of MgO on the furnace wall, and evenly spray a layer of slag on the furnace wall to protect the furnace lining.